Have you made a choice for a parquet, laminate or PVC floor? Then you must have already thought about (having) your floor placed! When laying your floor, many different factors play a big role on the end result. These factors include the laying pattern, making the right preparations and ordering the right products. We see that this is often underestimated, so you quickly run the risk of a less successful floor or even damage to your floor! In order to make you aware of this and to avoid such situations in your project, we have listed the most common mistakes made in the below.

Insufficient acclimatization

For both parquet, Laminate As a PVC, it is very important that your floorboards have sufficient opportunity in advance to acclimatize to the conditions in your home or office building. In this way, the floorboards can “get used” to the temperature and humidity. A temperature of 18-21 degrees with a humidity between 45 - 65% is optimal. At higher temperatures and humidity, the floorboards can expand or shrink and in extreme cases even crack and crack (laminate & Parquet).

Despite often being supposed to be different PVC flooring Also very sensitive to temperature differences, which makes acclimatization extra important for this type of flooring. In the conditions described above, make sure that the floor parts are placed in the space in which they will be installed for at least 48 hours. Spread the floor parts over the floor as much as possible or stack them in # bandage if necessary so that the air can flow through all suits.

Improper supplies & numbers of ordering

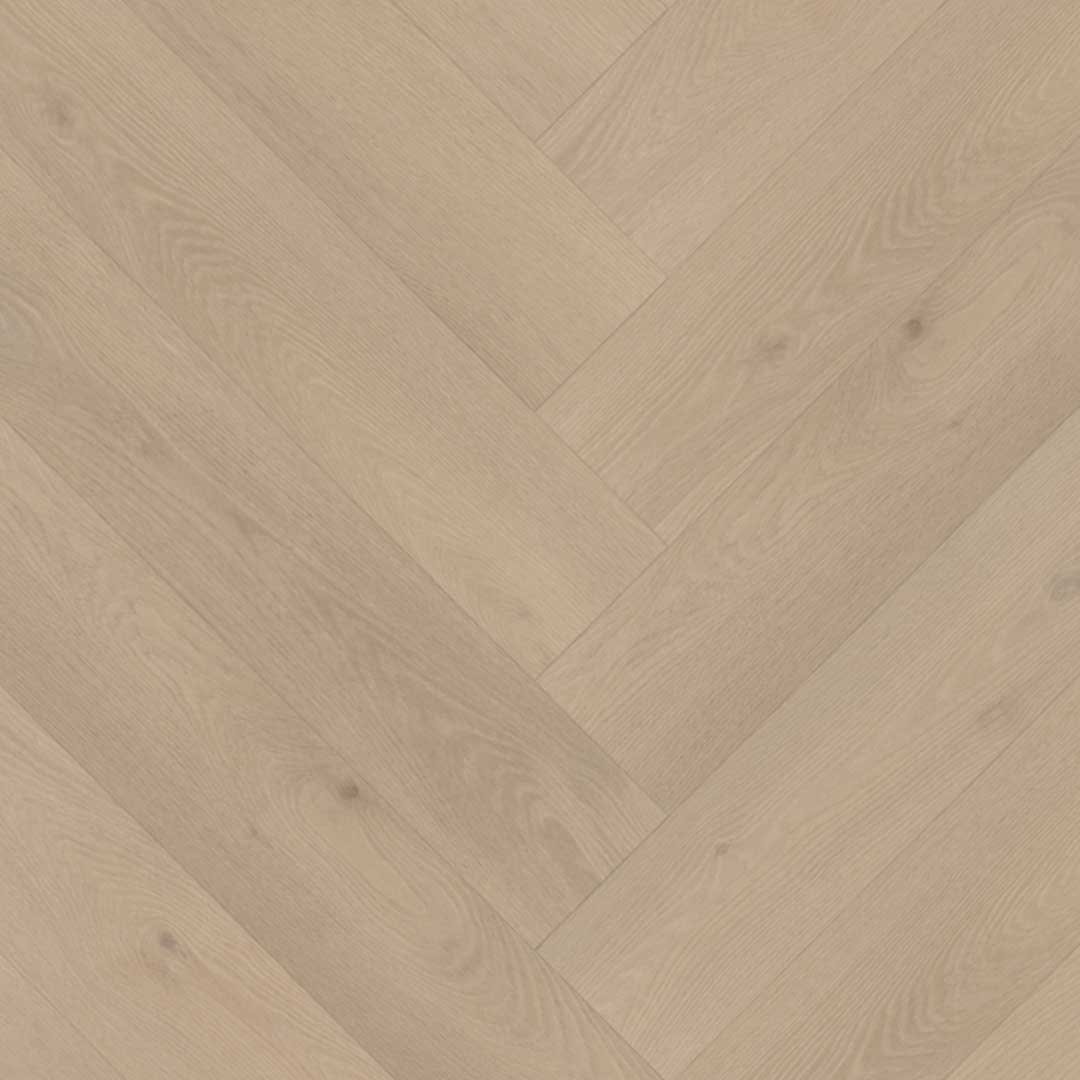

Parquet , Laminate and PVC floors we can subdivide different categories. Think of floating click floors or glued floors. With floating floors, your floor is placed on a suitable subfloor. Each type of floor and subfloor has its own specifications. So serves for a Click PVC Floor often a pressurized subfloor to be used as well as Herringbone Laminate. When placing a straight laminate floor, this is less important. However, also with these floors you can choose a sound-absorbing, insulating or contact sound-reducing Subfloor . With glued floors, it is important that you choose a suitable adhesive and the surface is sufficiently flat. For example, to level your surface, you can level the surface with egaline. In addition, a rubber hammer, legsets, a crosscut saw or laminate/PVC clippers are not a luxury when placing your dream floor. You can find a selection of these accessories in our accessories category!

In addition to ordering the right laying materials, the number of floorboards to be ordered is also of great importance. There is nothing more annoying if you find out during laying that you have brought too few floorboards to finish the job. To make sure you get enough floorboards for your job, we 've gathered more information about Calculate cutting loss and m2s needed on this page .

Laying too tight & unevenness in the surface

The advantage of glued PVC and some glued parquet floors is that you can lay these floors tightly against the wall, plinth or frames. For example, you hardly need adhesive skirting boards or deck moldings to finish your floor, which is often the case with Click PVC floors. Does this take into account the fact that a smooth and flat surface is extra important with glued floors. To achieve this, you can choose to level your surface before laying. This allows you to make the surface flat and even so that irregularities have little or no effect on your glued floor.

With Click PVC and Laminate floors you often have a bit more clearance in terms of unevenness in the surface. To level this out, you can of course also equalize. However, to save costs, you can also choose a subfloor that absorbs the biggest irregularities from your floor. Look carefully at the specifications of the underfloor and whether it is suitable for your chosen click floor! It is generally not recommended to combine different subfloors with each other. In addition, with floating click, you can not place floors such as parquet, laminate and click PVC in the base tightly against walls and frames. This means you run the risk that when the floor parts work, the floor can become convex, cracking noises or damage your floor in other ways. Keeps at least 1 cm of space between wall and floor and gives your floating floor plenty of room to move!

Any questions?

Do you have any questions or doubts about placing your floor? You can often find recommended laying instructions on the suits or the website of the manufacturer or supplier. We recommend that you go through it carefully and follow it up! You're not quite coming out, are you? Then we will of course be happy to help you through our handy blogs and our customer service! In addition, you can also use our laying service and have the installation of your Herringbone or Straight Parquet, Laminate or PVC floor performed by a specialist. If necessary, ask completely without obligation one Quote With us.